Definitions

• A Method or set of Techniques, Six Sigma has also become a Movement focused on Business Process Improvement.

• It is a Quality Measurement and Improvement Program originally developed by Mikel Harry and Richard Schroeder at Motorola in the early 1980's

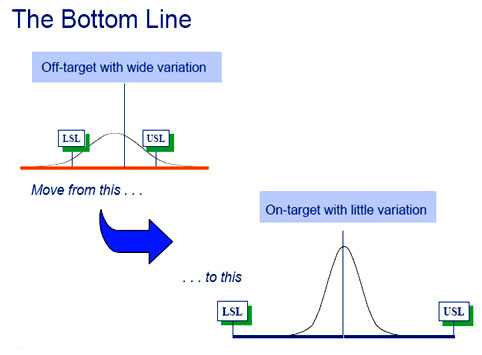

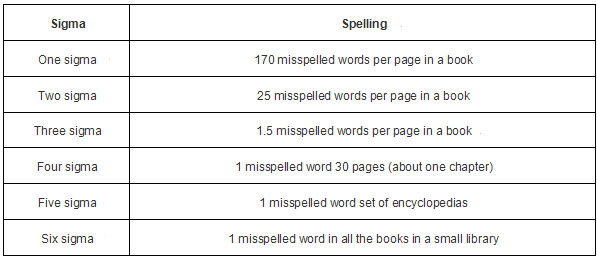

• It focuses on the Control of a Process to the Point of ¡À Six Sigma (standard deviations) from a centerline, or put another way, 3.4 defects per million items.

• A Six Sigma systematic quality program provides businesses with the tools to improve the capability of their business processes.

• It is a Business Process that allows companies to dramatically improve their bottom line by Designing and Monitoring everyday business activities in way that Minimizes Waste and Resources while Increasing Customer Satisfaction.

• A Customer-Focused, Data-Driven Leadership Strategy

• A Strategy - A Set of Tools - A Discipline - Leadership Development - A Common Language

• The Six-Sigma process was developed at Motorola as a structured, closed-loop, team-oriented application of the scientific method.

• This process was designed to assist teams in solving complex problems, using five steps in a sequential, closed-loop approach to improve process capability.

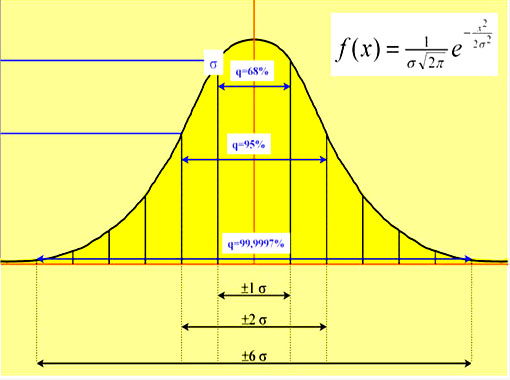

• Process capability is measured in terms of sigma, which refers to the extent that the output of a process falls within its specification limits.

• In statistical terms, sigma is a measure of variability, also known as standard deviation.

• Achieving six-sigma means that a process has three standard deviations on either side of its mean value inside of the specification limits.

• At that level, the process would be expected to produce only three defects per one million opportunities (the equivalent of having no "bad days during a lifetime, only a few "bad hours").

• The process is commonly used at Motorola, General Electric, Allied Signal, and many other Fortune 500 companies.

• The process is flexible within the 5 basic steps in that various improvement tools can be used at each step.

Six Sigma Fundamentals

• Define What The Customer Wants

• Measure The Key Output

• Analyze The Data

• Improve The Process

• Control The Process

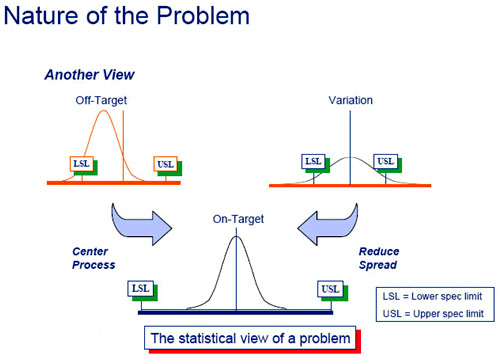

Nature of the Problem

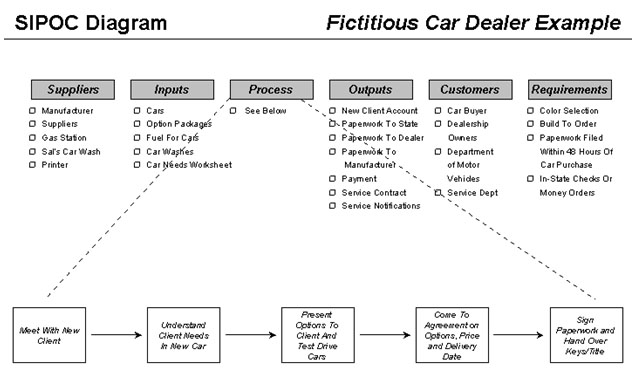

A Practical Example of Six Sigma

Why Do We Need Six Sigma?

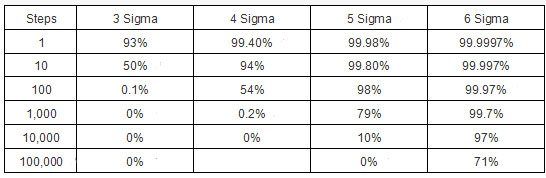

• Rolled yield: If there are 100 steps and each step is 99.4% good, the rolled yield is 54% good!

The more complex your process, the higher the required capability

Key Six Sigma Concepts

1. Critical to quality

What the customer wants

2. Defect

Failing to deliver what the customer wants

3. Process capability

What your process can deliver (entitlement)

4. Variation

Everything varies

5. Design for Six Sigma

Designing to meet customer needs and process capability

Six Sigma Quality and Productivity are Interdependent

The four fundamentals of Six Sigma

1. Process ¡ Everything Is Process

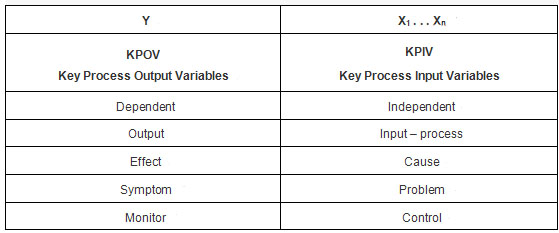

2. Correlation ¡ Y f(x1, x2, x3)

3. Discipline ¡ DMAIC

4. Data ¡ All Learning Resides In It

It Responds to Change By Driving Out Variation

The Focus of Six Sigma

To get results, should we focus our behavior on the Y or X ?

If we are good at X why do we constantly test and inspect Y?

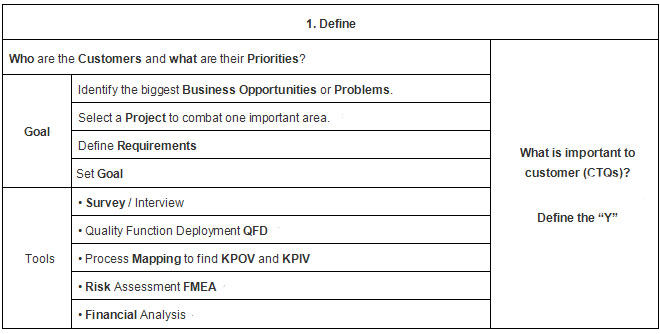

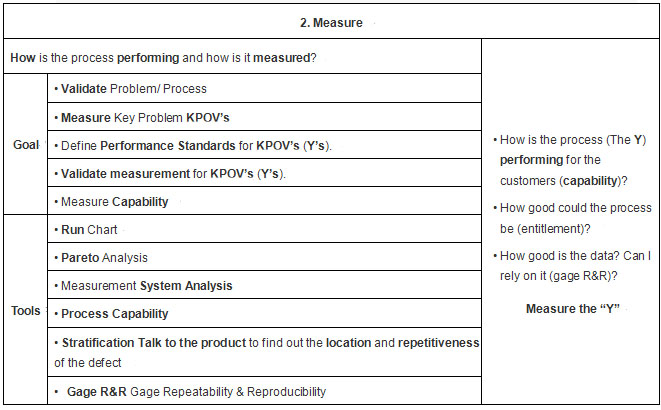

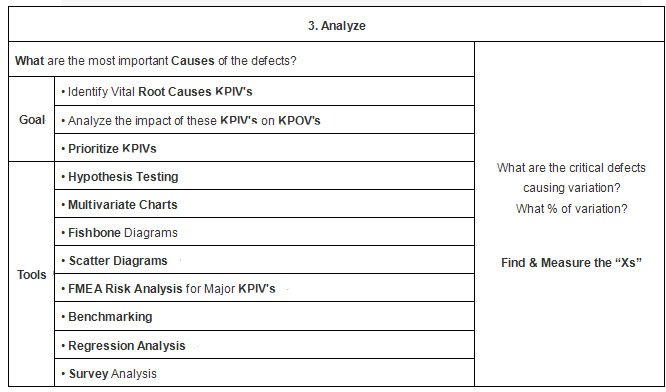

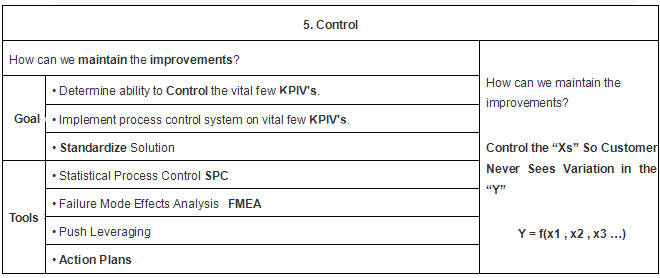

DMAIC

How do you implement Six Sigma

• Leaders Must Own and Use It

• Top Resources Selected into It

• Projects Tied to Customer/Shareholder Bottom Lines

• Business/Functions Manage with It Daily

• Everyone Trains ¡ Learns the Language

Get everyone involved in Six Sigma

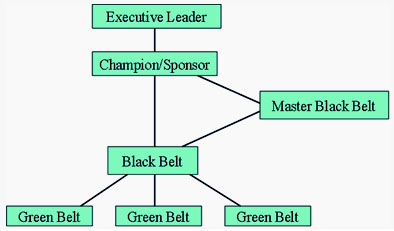

• Champions:

Fully trained business leaders who own the processes and lead the deployment of Six Sigma in a significant area of the business

• Master Black Belts MBB

Fully-trained, full-time cross-functional quality leaders who team with champions and are jointly responsible for Six Sigma strategy, training, mentoring, deployment and results

• Black Belts BB

Fully-trained, full-time Six Sigma experts who lead improvement teams, work projects across functions in all areas of the business and mentor Green Belts

• Green Belts GB

Fully-trained individuals who use Six Sigma skills to complete projects in their job areas

• Team Members

Individuals who receive specific Six Sigma training and who support projects in their areas

» More Information